Environment Health and Safety

The Company’s Environment, Health and Safety (EHS) initiatives are designed to create long-term sustainability and value for the Company, its shareholders and other stakeholders. Preserving the natural environment and promoting the well-being of the community are integral aspects of the Company’s business responsibility. The Company has also implemented the ‘CORE’ (Creating Optimal and Responsible Environment) programme, which has helped contribute to the larger goal of sustainable development.

ENVIRONMENT

PEL is committed to conserving resources as it recognises the importance of preserving the environment. We have Zero Liquid Discharge (ZLD) system at the key facilities. The Company has adopted the 'reduce, reuse and recycle' mantra for natural resources, and has developed adequate infrastructure to treat and reuse waste water. The CORE programme was launched to drive sustainability initiatives across Piramal Pharma Solutions. A few initiatives under the CORE programme are:

Energy Efficiency

Initiatives such as reduction in the power usages by using energy efficient alternatives, modifications in the utility pipelines, using timers to control light fixtures etc. resulted in reduction of carbon footprint. These initiatives have resulted in overall power consumption reduction by 2%.

Water Conservation

Initiatives such as steam condensation to recirculate to boiler, modifications in manufacturing processes and use of efficient alternatives to reduce tap water flow. These initiatives have resulted in overall Water consumption reduction by 3%.

Waste re-use and re-cycle rate increased by 5% in FY2019

- 100% Non-hazardous waste sent for recycling

- Increased tree plantation by 3% over the previous year

- CO2 offset by tree plantation by 3%

HEALTH

- Health of employees and contractors is monitored through pre-medical check-ups and periodic medical check-ups.

- Employees are provided counselling after every medical check-up by a factory medical officer.

- The Company commenced a risk-based employee assessment programme to assess chemical concentration exposure to employees.

SAFETY

The Company ensures the well-being of its employees, partners, and visitors to its offices. A safe working environment is non-negotiable at PEL, for which it follows global safety standards in all its operations. The Company has been achieving continuous improvements in safety performance through a combination of systems and processes as well as cooperation, involvement and support of all employees. During the year, there was no fatal injury at any site. The First Aid Injury Rate (FAIR) and Total Recordable Injury Rate (TRIR) decreased during the year.

Risk assessment and management

Safety is periodically reviewed at the enterprise level while the sites have deployed structured risk assessment and management processes. Hazards are identified using techniques such as Hazard and Operability Study (HAZOP), Hazard Identification and Risk Analysis (HIRA), What-if-Analysis, Failure Mode Effect Analysis and are addressed by following the hierarchy of risk control. Unsafe conditions and hazards are reported and tracked for their completion. Employees working in high-risk areas are given specialised training and retrained periodically. Business continuity plans are in place to manage crises.

Building our Safety and Health competency

Health and safety considerations are integrated in overall management systems and are an important driving force for our operations. The standards for best practices in health and safety are visible, robust, sustainable, and subject to continuous review.

Incident Statistics

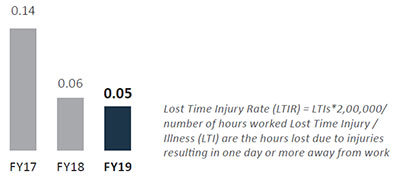

Loss Time Injury Rate

Enhancing Near-miss Reporting

An efficient indicator of risk reduction that shows the organisational bent towards improving the EHS culture. For FY2019, we increased our near miss reporting by 10%.

Near-miss reporting

Developing an EHS Learning Culture

The Company invests resources and efforts into training and hardware upgradation to improve its safety performance every year. The total training man-hours exceeded 10% of the target in FY2019.

Safety Training Man-hours Per Person Per Year